Powder Metallurgy material have the unique chemical composition and physical and mechanical properties that can not be get by the traditional casting process. For example, the porosity of the material can be controlled, uniform material

structure and no macroscopic segregation occurs (different parts of the alloy have no macro- Flow caused by uneven chemical composition), can be a molding and so on.For powder metallurgy spare parts, the main factors that decisded the level

of mechanical performance is density of sintered parts, any factors that increase the density of the sintered part, it can improve the mechanical performance of final parts. The greater density of sintered parts, the higher the mechanical

properties,If the density of sintered parts can't achieve the theoretical density of the corresponding dense material, the material mechaniccal performance of sintered parts will lower than the mechanical performance of corresponding dense

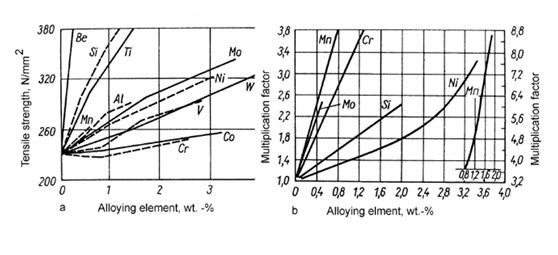

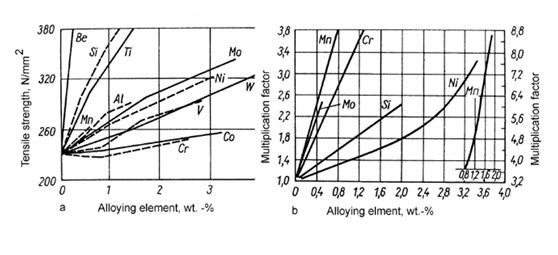

material.Such as steel, it should note carbon steels (iron-based sintered materials made of iron and carbon) and sintered steels added with alloying elements, its strength is increased with the increase of alloying elements,but toughness and impact

energy value will be low.Thus,the toughness and impact energy value of iron powder metallurgy structure material decrease with decreasing material density and increasing content.

During production of powder metallurgy structure parts, it always use re-pressing and second-sintering to improve material density of parts, re-pressing is similar with precision-shaping, it need throw higher pressure when re-pressing, it just

improve the whole density of part's material. It can remove the influence of cold hardening through second- sintering.Secondary sintering refers to re-sintering after re-pressing.Thus, The structure parts with re-pressing and secondary sintering can

improve its strength and toughness because of higher material density.